Researchers produce carbon from sugarcane waste for use in batteries

Researchers from Pune (Maharashtra) have produced high-quality carbon from sugarcane waste within minutes by using a low power microwave system.

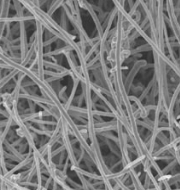

They had used a simple, cost-effective and quick process to convert sugarcane bagasse into anode-grade porous, conducting, activated carbon material for use in Li-ion batteries.

What they achieved it?

- They had carried out initial carbonisation overnight at room temperature by mixing bagasse with concentrated sulphuric acid.

- The acid treatment had dissolved most of the inorganic impurities present in bagasse except silica. This helped in forming robust carbon double bond backbone structure.

- The solid product obtained from acid treatment was washed thoroughly and was oven-dried at 70 degree C. Later it was mixed with potassium hydroxide to form slurry.

- The slurry is then heated in a microwave oven for a few minutes. The heating had led to graphitisation and pores were formed when potassium hydroxide reacts with carbon.

Significance of Research

- The process will bring down the time to get anode-grade carbon dramatically. Thus, it will help to reduce electrical energy input substantially.

- The quality of carbon and battery performance using this carbon is quite good and competitive compared with carbon made through other complicated schemes and processes.

- The carbon was produced using Simple kitchen microwave used to derive high-quality material in minutes.

Month: Current Affairs - September, 2016