Gujarat’s First Semiconductor Assembly Plant Opens

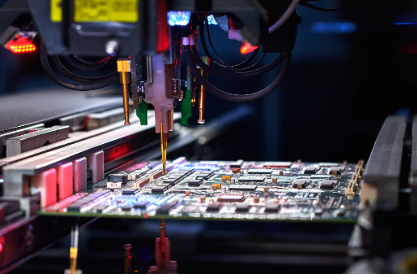

Suchi Semicon has inaugurated Gujarat’s first Outsourced Semiconductor Assembly and Testing (OSAT) plant in Surat, marking an advancement in India’s semiconductor manufacturing landscape.

Plant Overview

The OSAT plant covers an area of 30,000 square feet and provides essential services like assembling testing, and packaging semiconductor components. These services cater to various industries, including automotive and consumer electronics.

Government Support

Union Minister C.R. Patil and Gujarat’s Home Minister Harsh Sanghavi inaugurated the plant. Prime Minister Narendra Modi praised Suchi Semicon’s efforts to enhance India’s semiconductor capabilities. This initiative aligns with the Atmanirbhar Bharat vision, aiming to reduce import dependency.

Suchi Semicon invested $100 million in the new facility. The plant aims to produce up to 3 million semiconductor chips daily. The company plans to partner with technology experts to optimise operations and encourage innovation.

Job Creation and Economic Impact

The plant is expected to generate approximately 1,200 jobs over the next five years. It is part of Gujarat’s Electronic Policy and the India Semiconductor Mission, supporting self-reliance in technology. Local leaders anticipate that this development will drive economic growth in the region.

GKToday Notes:

- OSAT: Outsourced Semiconductor Assembly and Testing (OSAT) refers to services for assembling, testing, and packaging semiconductor components. It plays important role in the semiconductor manufacturing supply chain.

- Atmanirbhar Bharat: Atmanirbhar Bharat is a government initiative aimed at achieving self-reliance in various sectors. It focuses on reducing dependency on imports and boosting domestic manufacturing capabilities across India.

- Gujarat’s Electronic Policy: Gujarat’s Electronic Policy supports the growth of the electronics sector. It aims to attract investment, create jobs, and establish the state as a leading hub for technology and manufacturing.

- Cleanroom Environments: Cleanroom environments are controlled spaces with minimal pollutants. They are essential in semiconductor manufacturing to ensure product quality and reduce contamination during the production process.

Month: Current Affairs - December, 2024

Category: Economy & Banking Current Affairs