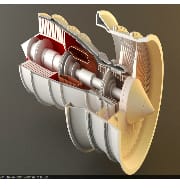

World’s first 3D-printed jet engine developed in Australia

Researchers from Australia’s Monash University have created world’s first 3 Dimensional (3D) printed jet engine.

The first of kind 3D printed engine was developed by team of researchers from Monash Centre for Additive Manufacturing in partnership with spin-out company Amaero Engineering.

Process of Production

- The jet engine was created using innovative additive manufacturing technique. Firstly, the scanned computer models of engines were created by the researchers.

- Then the 3D printing machine incorporated with high-powered laser fused the nickel, titanium or aluminium into the shape of engine parts.

Significance of this development

- It opens the door for engineers to make and test parts of jet engines in days instead of months.

- It will also help engineers to manufacture cheaper, lighter and more fuel-efficient jet engines.

About 3D printing technology

- 3D printing is a process of making three dimensional solid objects from a digital file with extreme precision.

- This technology is also termed additive manufacturing as the 3D printed object is created us additive processes.

- In an additive process an object is created by laying down successive layers of manufacturing material on each other until the entire object is created.

- This technology has limitless possibilities and can create almost anything with just raw material and a computer generated model.

Month: Current Affairs - February, 2015